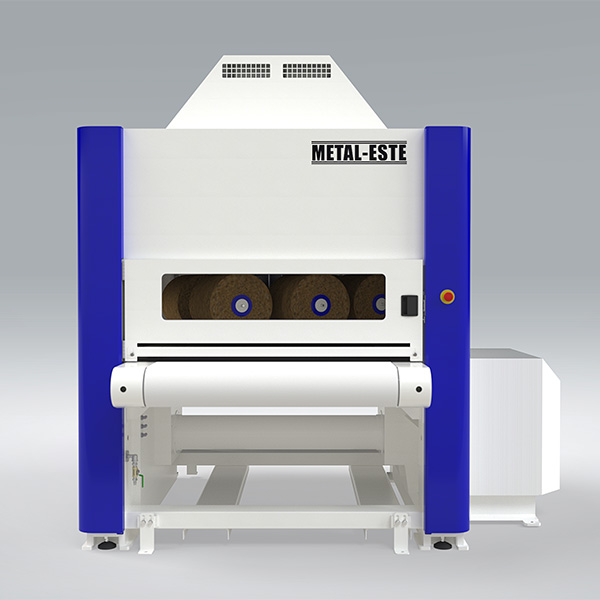

画期的な研磨方法

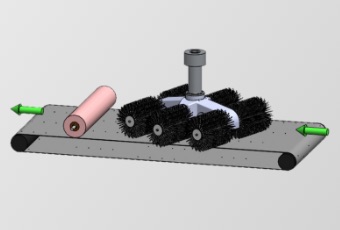

6本の研磨ブラシが回転しながら旋回運動を行うことで多方向から研磨。ワークに傷が付きにくく、二次バリの発生がありません。

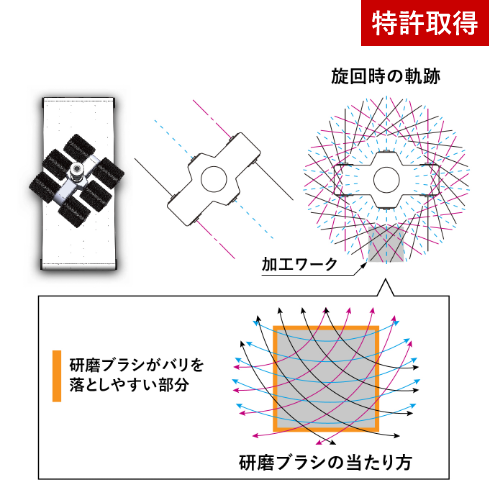

メタルエステ1000は従来構造に比べ、ブラシ回転軸が旋回軸に交わらず偏心させているため、コンベア上のどのエリアを流れるワークに対しても様々な角度で研磨ブラシが当たり、満遍なく研磨することが可能です。

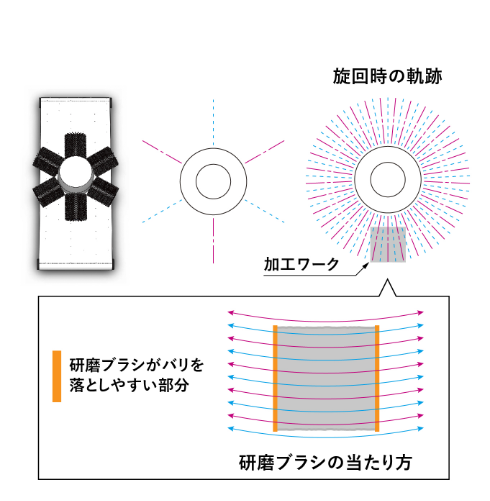

従来例

ブラシ回転軸が放射状に配置された場合、ワークと研磨ブラシとが常に同じ角度で接触するため、バリの取れ方に偏りが生じることがあります。

メタルエステ1000

ブラシ回転軸が偏心しているため、あらゆる角度から研磨ブラシが当たり、万遍なく研磨することが可能です。

新コンベアベルト

グリップ性能が大幅に向上。ワークをしっかり固定します。

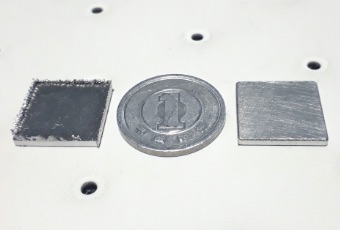

小さなワークも加工可能

従来は固定できなかった小さなワークも、コンベアベルトのグリップ性能を大幅に向上させたことにより加工が可能になりました。

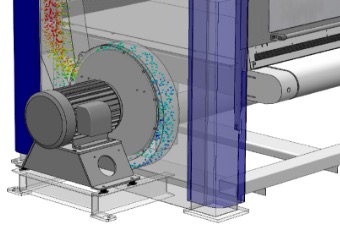

強力な吸引固定力

独自設計の改善を重ねたブロアが、吸着力を生みます。

6軸研磨ブラシ

圧倒的な加工均等性と6軸研磨ブラシの融合。

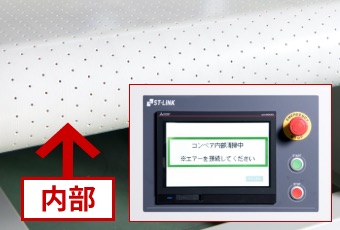

コンベア内部清掃機能

コンベア内部を清掃することで、性能・安全性を維持します。

大型タッチパネル

視認性・操作性の向上、自動基点設定やエラー発生時の図解サポートなど、内蔵プログラムの機能を大幅にアップデートしました。

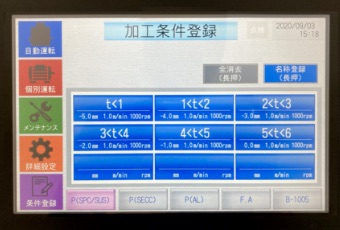

加工条件登録機能

昇降、コンベア速度、ロータ回転数の組み合わせを45条件(5グループ×9個)まで登録可能です。

自動基点設定

研磨ブラシの高さ、毛の長さをバリ取り機が自動で検知し、基点を設定します。

研磨ブラシは工具不要でワンタッチ着脱

簡単でスピーディー。様々な特性のブラシもストレスなく交換可能です。

ワークの材質・求める仕上がりに合わせて機械の能力を最大限に発揮できます。

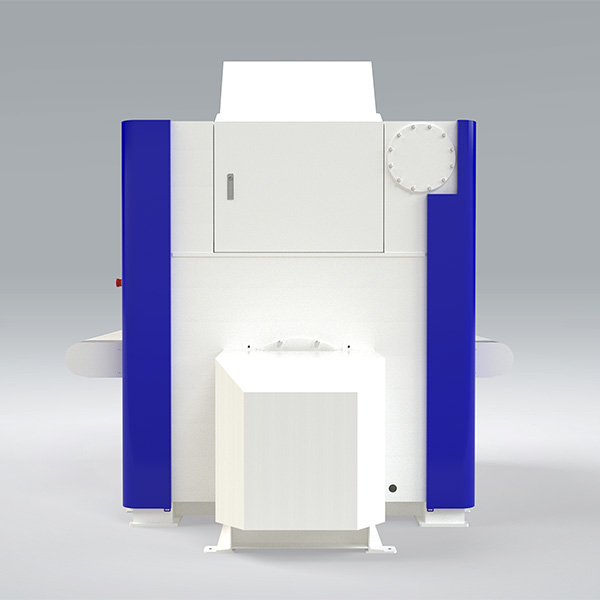

自社製造の高性能集塵機

オートパルス(フィルター自動清掃)機能を標準装備。集塵機の性能を維持し、機械、工場環境、作業者を粉塵から守ります。

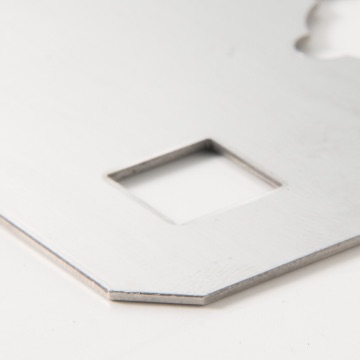

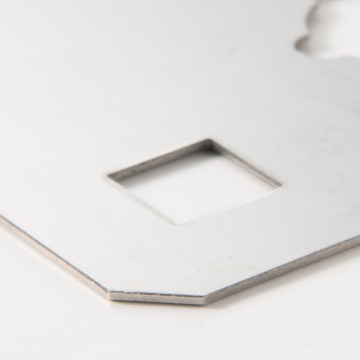

バリ取り・R仕上げ

■使用ブラシ:F-1504SP

加工前

加工前

加工後

加工後

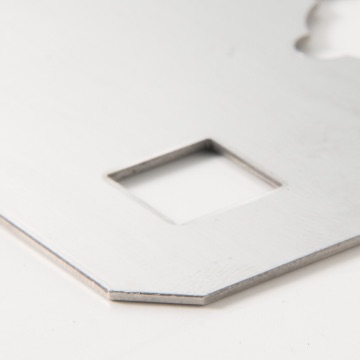

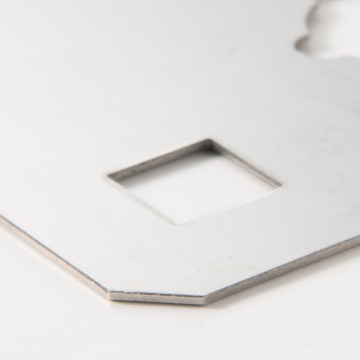

バリ取り・R仕上げ

■使用ブラシ:F-1504SP

加工前

加工前

加工後

加工後

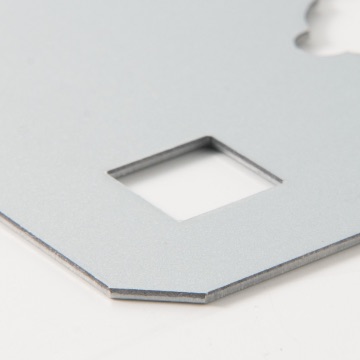

バリ取り・R仕上げ

■使用ブラシ:A-1803J

加工前

加工前

加工後

加工後

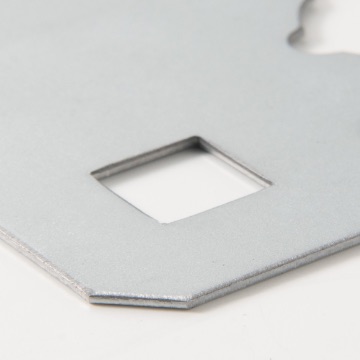

バリ取り・R仕上げ

■使用ブラシ:A-1803J

加工前

加工前

加工後

加工後

バリ取り・R仕上げ

■使用ブラシ:F-1504SP

加工前

加工前

加工後

加工後

バリ取り・R仕上げ

■使用ブラシ:F-1504SP

加工前

加工前

加工後

加工後

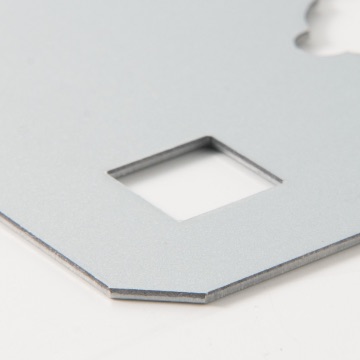

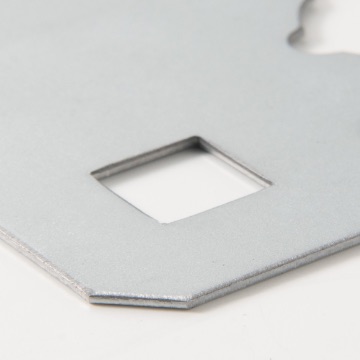

メッキ鋼板 キズレス加工

■使用ブラシ: P-1805

加工前

加工前

加工後

加工後

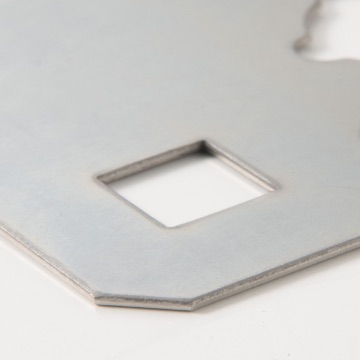

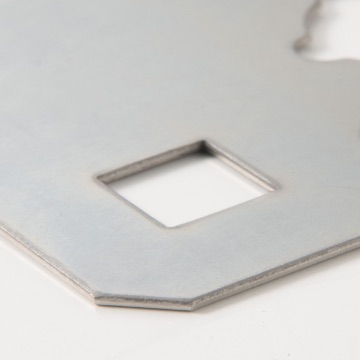

メッキ鋼板 キズレス加工

■使用ブラシ: P-1805

加工前

加工前

加工後

加工後

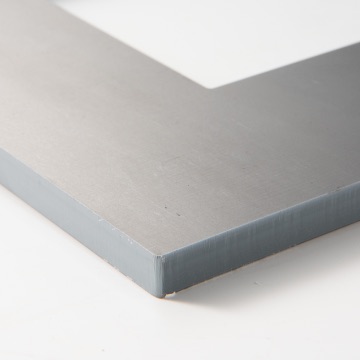

ステンレス・2B キズレス加工

■使用ブラシ:P-1805

加工前

加工前

加工後

加工後

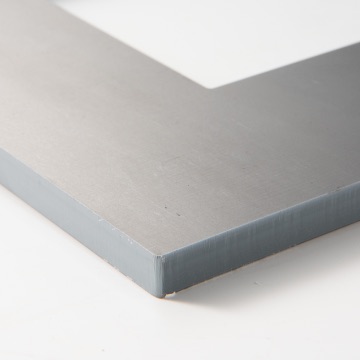

ステンレス・2B キズレス加工

■使用ブラシ:P-1805

加工前

加工前

加工後

加工後

シール材

■使用ブラシ:F-1504SP

加工前

加工前

加工後

加工後

シール材

■使用ブラシ:F-1504SP

加工前

加工前

加工後

加工後

成型(バーリング・ダボ)

■使用ブラシ: P-1805

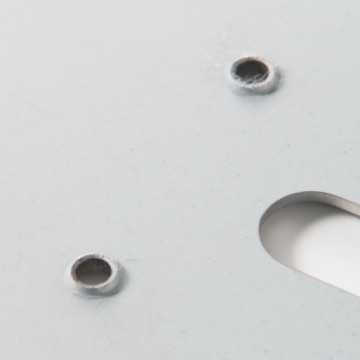

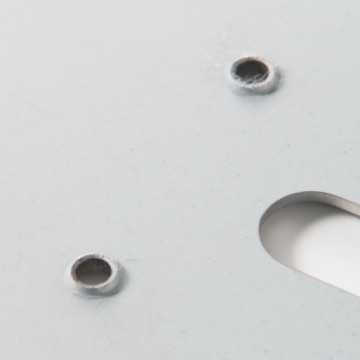

加工前

加工前

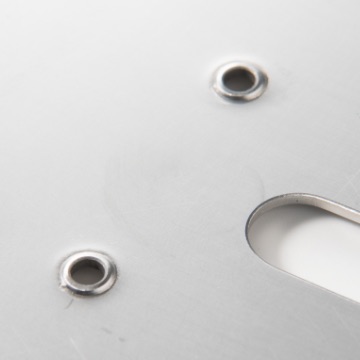

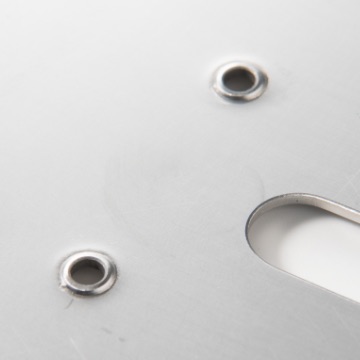

加工後

加工後

成型(バーリング・ダボ)

■使用ブラシ: P-1805

加工前

加工前

加工後

加工後

成型(バーリング・ダボ)

■使用ブラシ:P-1805

加工前

加工前

加工後

加工後

成型(バーリング・ダボ)

■使用ブラシ:P-1805

加工前

加工前

加工後

加工後

酸化被膜

■使用ブラシ:ワイヤーブラシ

加工前

加工前

加工後

加工後

酸化被膜

■使用ブラシ:ワイヤーブラシ

加工前

加工前

加工後

加工後

小物ワーク

■使用ブラシ:A-1803J

加工前

加工前

加工後

加工後

小物ワーク

■使用ブラシ:A-1803J

加工前

加工前

加工後

加工後

小物ワーク

■使用ブラシ:A-1803J

加工前

加工前

加工後

加工後

小物ワーク

■使用ブラシ:A-1803J

加工前

加工前

加工後

加工後

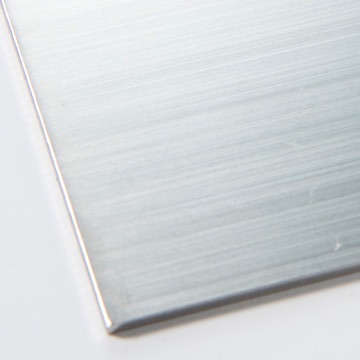

ヘアライン加工

■使用ブラシ:A-1803J

加工前

加工前

加工後

加工後

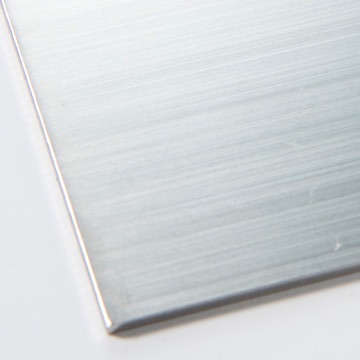

ヘアライン加工

■使用ブラシ:A-1803J

加工前

加工前

加工後

加工後

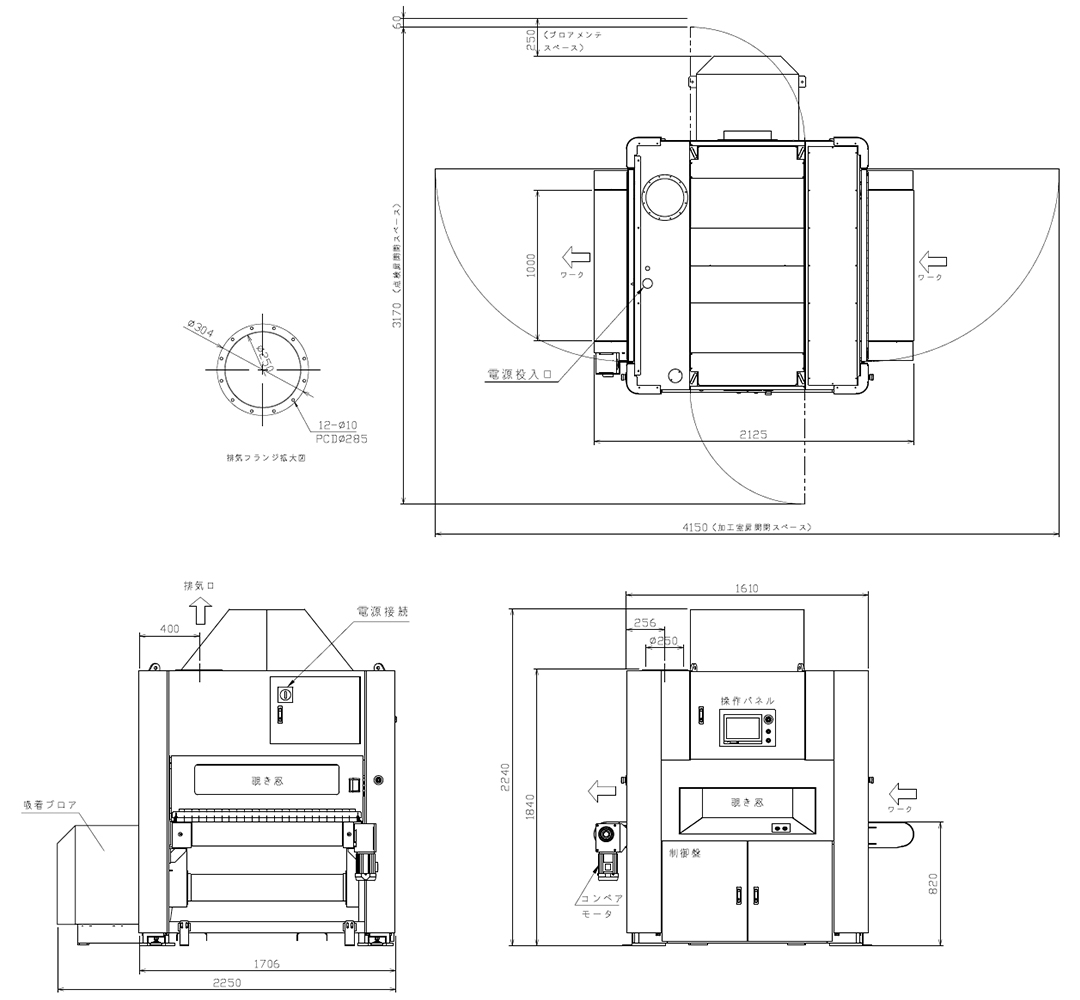

寸法図

性能諸元

| 型式 | ME-2308 |

|---|---|

| 最大ワーク幅 | 1000mm |

| 最大ワーク高さ | 70mm |

| 機械重量 | 1850㎏ |

| コンベア速度 | 0〜4.0m/min |

| 電気容量 | 17.5kW |

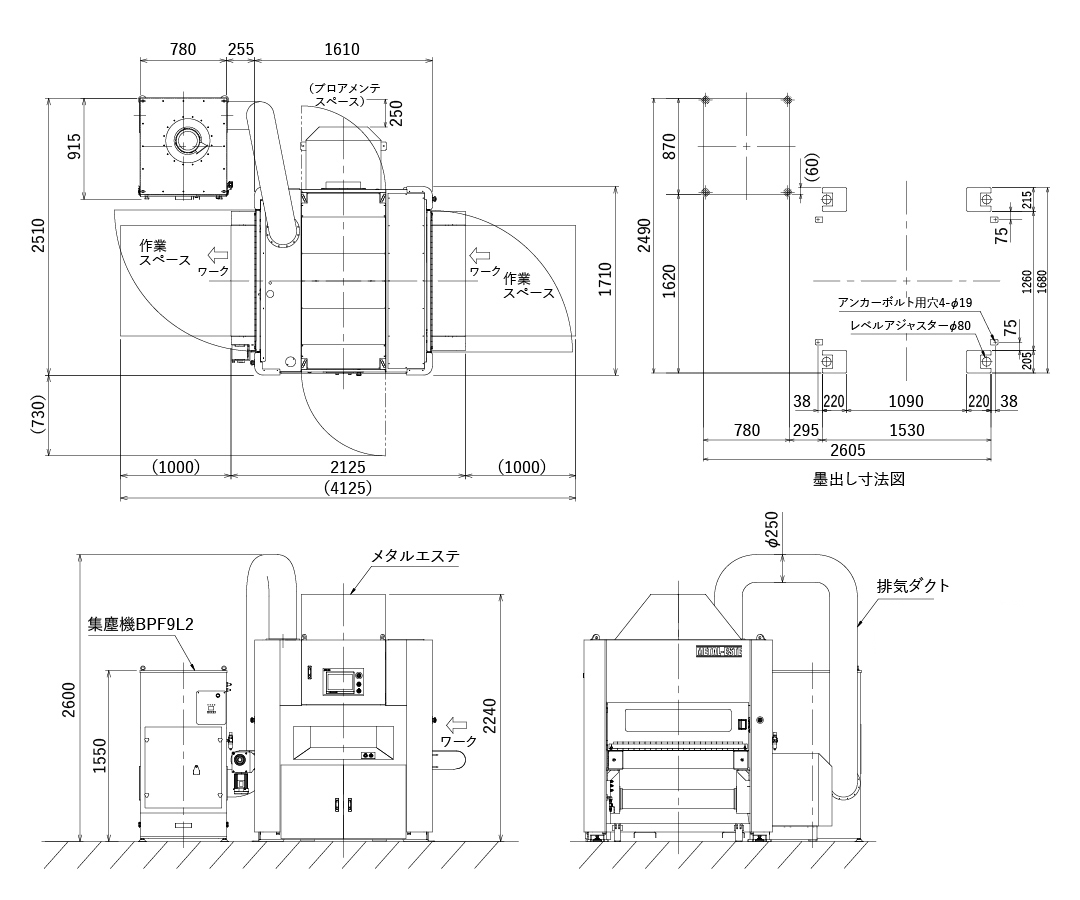

レイアウト提案図

様々なバリの強さ・仕上がりの要望に対応できるように、国内外の様々な研磨布を用いてバリ取り機にベストなブラシを追及をしています。メタルエステは剛性のあるギア回転機構によってφ350大口径ブラシの装着を可能とし、キズレス加工・強力研磨・酸化被膜除去を可能にします。

メタルエステ専用ブラシ

| P-1805 | P-1803 | B-1805-32 | A-1803J | F-1504SP | B-1005 | ワイヤーブラシ | |

|---|---|---|---|---|---|---|---|

| 外観図 | |||||||

| 番手 | #180 | #180 | #180 | #180 | #150 | #100 | - |

| ブラシ径 | φ350 | φ350 | φ320 | φ300 | φ300 | φ350 | φ350 |

| スリット幅 | 5mm | 3mm | 5mm | 3mm | 4mm | 5mm | - |

| 表面 | キズレス | キズレス | キズレス | キズ消し | 荒仕上げ | 荒仕上げ | 荒仕上げ 酸化被膜除去 |

| 最高回転数 | 1250rpm | 1250rpm | 1200rpm | 1200rpm | 1500rpm | 1200rpm | 800rpm |

| 推奨回転数 | 700〜1000rpm | 700〜1000rpm | 700〜1000rpm | 1000〜1200rpm | 1200rpm | 1000〜1200rpm | 700〜800rpm |

| 参考切込値 | 新品時2〜3mm 慣らし後5mm |

新品時2〜3mm 慣らし後5mm |

新品時2〜3mm 慣らし後5mm |

3mm | 3mm | 3mm | 10mm以内 |

| 研削強さ | 4 | 3 | 3 | 3 | 5 | 5 | - |

| 耐久度 | 5 | 4 | 3 | 3 | 3 | 4 | 2 |

| 細部加工 | 2 | 3 | 2 | 4 | 5 | 4 | 3 |

| 特長 | ペーパー幅が広く、切削力の強いブラシです。ワーク表面の傷を抑えながらバリを取る加工に適しておりステンレスやメッキ処理鋼板のバリ取りにも適しています。 | ペーパー幅が狭く、細い隙間や角まで届くブラシです。 ワーク表面の傷を抑えながらバリを取る加工に適しておりステンレスやメッキ処理鋼板のバリ取りにも適しています。 |

コストパフォーマンスに優れたブラシとなります。 ワーク表面の傷を抑えながらバリを取る加工に適しておりステンレスやメッキ処理鋼板のバリ取りにも適しています。 |

研磨痕が細かく、ワーク表面を滑らかに仕上げるブラシです。 | 最も研削力の強いブラシです。R面を大きくとりたい加工にお勧めです。 | 大口径のブラシで耐久性もあり尚且つ研削性もあります。 | レーザー切断時、端面に付着した酸化被膜を除去するブラシです。塗装剥がれ対策、溶接前処理にお勧めです。※対象ワークは板厚4㎜以上。※コンベアベルトに押し当てない様ご注意ください。 |

- Pブラシはワーク表面キズを抑える特性がありますが、使い始めは砥粒が強く、ワーク表面に研磨痕が入ります。メッキ鋼板などを加工する場合は、ブラシを適度に慣らしたのちにご使用ください。

- ブラシ発送には別途送料が発生します。

- ブラシ納期は通常で受注後2週間程度です。但し、在庫状況によっては納期変動もありますのでご了承ください。

- 上記ブラシがメインとなります。その他ブラシについては営業にお問い合わせください。

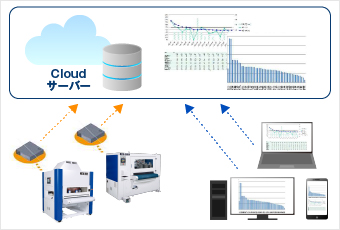

IOT稼働監視機能

【画像クリックでデータ画面例が開きます】

バリ取り機の稼働データをサーバーへ送信。

稼働時間などのデータを見える化し、生産性の向上や予知保全などに効果を発揮します。

異常時にはメーカー側とデータを共有する事で問題の早期解決も可能となります。

外付けアーム式操作盤

操作盤をアーム先端に取り付ける事により、自由な位置から機械の操作が可能になります。

タブレット操作

自由な場所から加工条件の変更が可能。ホルダーで任意の場所に固定することも可能です。

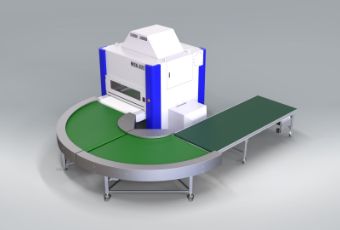

リターンコンベア

コンベア入口側でバリ取り機にワークを投入しながら回収まで行うことができます。

数量の多い小物作業に対して作業効率アップを図りたい場合に適しています。

(シュートの利用を推奨)

リターンコンベア(Jターン型)

ワークを落下せずに投入側までリターンできます。

繊細なワークや治具にセットしてバリ取り加工するワークにもお勧めです。

洗浄機

水・アルカリ両対応のマルチ洗浄機。油、指紋、汚れなどを綺麗に洗浄。タップ油も除去できます。

メタルエステのコンベアから洗浄機への受け渡しもコンベアtoコンベアでスムーズに受け渡し。バリ取りの前後工程に活躍します。

粉塵除去装置

バリ取り加工時にワークに付着した粉塵を除去します。(ブロア式)

ワークに粉塵が付きやすい「マグネットコンベア」との連携もお勧めです。

集塵機と連携することで周囲への粉塵飛散も防ぎます。

自動消火装置

バリ取り機は大量の粉塵を発生する装置です。鉄粉は第2類危険物に該当し、油分が混ざることで 燃焼リスクが増します。熱センサー、炭酸ガスなどを装備することで万一の火災を自動消火します。

集塵機の仕様変更

爆発対策型集塵機や湿式集塵機など、お客様の加工ワークに最適な集塵機をご提案します。

リターン用シュート

【画像クリックで動画が開きます】

ワーク落下時の衝撃からコンベアベルトを保護し、角度調整機能により様々な形状、サイズ(ワーク長さMAX550㎜まで)のワークをスムーズにリターンさせることができます。

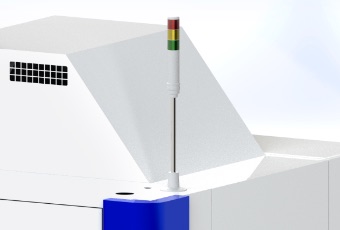

シグナルタワー

装置の状態が遠くからでも一目瞭然。

警告時には光と音で知らせるため毎日の作業をより安全・安心なものとします。

安全に配慮したその他スイッチの追加、ブザーの追加、鏡の設置なども承ります。

マグネットコンベア

強い磁力で吸着することにより、小さなワークでも冶具を使わずに固定することができます。

※対象ワークは鉄など磁力で固定できる材質に限ります。

バーコード読み取り機能

バーコードを読み込ませる事で任意の条件に変更できます。

板厚検知

ワーク投入前に板厚を測定し、板厚に合わせて最適な切込み高さに自動制御する機能です。

ワーク投入部の板厚測定台にワークを置くだけで自動で高さが設定されます。

通常の高さ設定と比べて格段に作業効率が上がり、高さの設定ミスも防ぐことができます。

仕上げ機構

仕上げローラーを搭載し、バリ取りから表面仕上げまで一度に加工が可能です。

素材・板厚・サイズなど具体的にお知らせください。

※テストピースも受け付けております。

その後、メタルエステで加工したサンプルをご返却いたします。

仕上がりをご確認ください。

ご契約から納品までは、およそ2ケ月かかります。